SVT COBRA MUSTANG CLUBô

Throttle Body University

by Kenny

Parker

The stock throttle body on late model Cobras has twin bores of 57 millimeters. So I decided that I wanted to replace mine with one that has twin 62 mm bores.

Here is a picture of the stock throttle body next to the aftermarket one.

I installed the new throttle body on my 1999 Cobra. The throttle bodies for the newer Cobras are all the same. If your car is a bit older, then some of the adjustment advise here may not apply to your car. On newer cars the adjustments listed here should work.

The throttle bodies sold by BBK and Edlebrock are virtually identical. They are both manufactured by BBK. The only difference between the two is the engraving of the name. Buy whichever one you can get cheaper.

The biggest problem I had installing my throttle body was getting the car to idle right after it is installed. After weeks of troubleshooting, here is the most valuable piece of advice I have. Before you remove the old throttle body, check the voltage that it reads when the butterfly is fully closed. Then when the new throttle body is installed, get the voltage to match the previous reading as closely as possible.

To check this voltage you turn off the radio, heater/ac etc. and turn the ignition to the "on" position but with the car not running. The battery has to be hooked up for this step, but the negative terminal should be disconnected for all other steps while installing the new throttle body. Take a multimeter and attach the positive lead to the center wire of the connector to the TPS. Set the multimeter on the 20 volt DC scale.

Here is a picture of how to do this.

Now intall the connector on the TPS and touch the black lead to something grounded. The multimeter should read somewhere around 1 volt.

Write this value down somewhere and refer back to it later.

The next thing you want to do when you receive your throttle body is do both of the required adjustments. On the side of the throttle body where the throttle cable linkage is, there is a set screw that adjusts how far the butterfly valve can close. Set this screw such that the butterfly valve closes as far as possible without sticking when first opened. Donít worrry about this setting too much because your going to set it with the multimeter later. Next is the gold screw at the bottom/top. If your car is a 1999 then this screw is on the bottom. If your car is a 96-98, then this screw is on the top. The throttle body is actually installed upside down on the 1999s. Screw this screw all the way in. Once this is screwed in all the way, you should not be able to blow through the smaller of the two holes between the 62 mm bores. If you can blow through this hole, you have problems. Your car will never idle right. Either replace the part, or buy some high temp silicone RTV and plug the hole. If you choose to plug it, make sure the RTV cures for at least 12 hours. If this is not completely hard, it will be sucked into the engine.

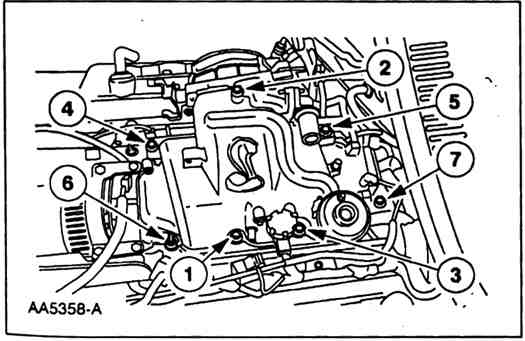

The throttle body is mounted up to the upper intake manifold. The upper intake also has twin holes in it. To achieve maximum benefit from your new throttle body, you need to increase the size of the bores in the upper intake to also be 62mm. Removal of the upper intake is not hard. There are seven screws that hold it on. These should be installed and removed in a star pattern.

Here is a picture of the removal sequence recommended by Ford.

Before you remove the upper intake you have to remove all the things that are mounted to it. There is one vacuum line that goes to a big black valve of some sort on the back of the intake manifold, on the drivers side. I was not able to get this off. Rather than removing the two screws that hold it in place, instead remove the big line that attaches to the bottom. I used a very large adjustable wrench because the largest wrench I had was 22 mm and it was not big enough. It came off pretty easily. Once you have removed all the things that mount to the upper intake, remove the bolts that attach the upper intake in the star pattern shown above and then remove the upper intake.

I used a Dremel tool with the sandpaper bit to increase the size of the bores in the intake manifold. I matched up the parts and used a pencil to mark where the material needed to be removed and then slowly sanded it off with the Dremel tool. This took an hour or two. Before you start this, I recommend that you put something in some of the holes in the intake manifold to keep the aluminum dust out of them. Then I used 400 grit sandpaper and a little water and wet sanded the bores until they were totally smooth. Finally I cleaned the entire part really well. Any cleaner will do. I had a big can of Berrymans so I cleaned the entire part with that. This is the most important step of all. Be very careful to not get metal particles in the holes where you canít clean it very easily and then make sure the part is very clean after itís been modified. The whole job was pretty easy really, but this is a big risk. If you get metal particles sucked into your engine, it can be disastrous.

So, by now I assume you have an adjusted throttle body, and an upper intake with larger intake holes in it. The next thing to do is to install the Throttle Positioning Sensor. You will need to use an impact screwdriver to get the screws out since Ford used Locktite when they installed them. I put mine in a vice with wood blocks so that it didnít get torn up and then used an impact screwdriver. It worked very well.

Once you have the throttle position sensor removed, install it on the new throttle body. First you have to press the black plastic ring into the new throttle body.

Here is a picture of the black ring.

The way I did this was to set it on top of the hole where the TPS goes and start the screw threads into their holes. Then once I had everything lined up, I tapped the TPS with a rubber mallet. This kept everything lined up while it go started into the hole. Then I just alternated tightening the screws until the whole thing was inserted. Now the black ring and the TPS are installed correctly. Tighten the screws until they are very slightly snug. Weíll tighten them fully later.

Now, check the voltage on the TPS with the butterfly valves fully closed and make adjustments required to get a voltage that is the same as the stock throttle body. When you set the set screw for the idle, it was hopefully set so that there was virtually no gap around the butterfly valves when they are fully closed, but that they donít stick when they are first opened. If thatís true, then the first thing you want to do while the multimeter is showing the voltage is to try to rotate the TPS to see if you can get a closer reading. There is a little slop in the mounting holes that allows it to move a little. If you canít get close enough, then adjust the idle set screw. Between these two adjustments, get the voltage as close as you can. In my case, I got it perfect. The set screw is set so that it barely sticks, but I canít tell it while driving. The TPS is adjusted so that the voltage is .93 volts, which is the reading I got before I removed the stock throttle body.

Editorial note here, the first time I installed my new throttle body, I got a reading of 1.4 volts. If you get this your car is never going to idle. Mine idled at 3000 rpm. Getting this adjusted properly is critical. Once you have it adjusted right, then tighten the screws mounting the TPS.

Once you have the TPS installed and a good volt meter reading, then install the throttle body on the upper intake manifold and reinstall the intake manifold back on the motor. The torque sequence for installation is the same as removal. Follow the torque sequence shown above and torque each bolt to 89 inch pounds or 10 newton meters.

Here is a picture of the torque wrench I bought to install these bolts.

I got it at Home Depot and it is different than most other torque wrenches because it has a scale for inch pounds instead of foot pounds. It is a Husky model 39102 and it came with the case shown in the picture.

Then install all the stuff that mounts to the upper intake. Donít forget the big metal hose that screws into the big black valve and donít forget the big black rubber hose that plugs into the bottom of the upper intake just by the throttle body. These two can be easy to forget.

Reinstall the air intake tube. The 62 mm throttle body has a slightly larger front side. I had considerable trouble getting the air hose attached. The only way I got this done was to remove the rubber seal and just mount the plastic hose up on the new throttle body.

Reconnect the negative battery cable that was disconnected before you ever started. Make sure the air conditioner, heater and radio are off. Start your engine and let it idle for 15 minutes. Then take it out for a drive. Your car is going to go through puberty right before your eyes. More things will be changing so fast you canít keep up with them. Even though I got the voltage exactly the same as with the stock throttle body, the car still knows something has changed. It will adjust things over and over while it tries to recalculate everything. At one light it would idle at 700 rpm and the next light it would be 1200 rpm. Sometimes it would even idle at 2000 rpm. For a while the computer would not let the air conditioner come on. It was the most weird 20 minutes that car has ever had. Then I turned off the motor and let it cool down. The next trip was better and the one after that was even better still.

You will notice the accelerator pedal is much stiffer than before. It took some getting used to, but Iím about comfortable with it.

I am happy with the performance. The car does seem to run stronger, but I have not had it dynoed yet. The "seat-of-the-pants" meter, however, says it can feel the difference. All in all it took several weeks to get this mod done. And it was a major pain in the butt. However, this paper will make your install much simpler. The adjustments described above should make your life very much simpler than mine. Most of the time I spent doing this mod, was in sending the part back to BBK and waiting weeks for them to investigate what turned out to be a phantom problem. The problem turned out to be the set screw that sets the butterfly valve at idle. There is a real difference of opinion here. What I thought was very closed, the engineer at BBK thought was very open. Thatís why I described the tests above. If you follow the tests with the multimeter and set the TPS and the idle set screw as described above, then your install should be easy. I sure wish someone had told me all this!

Notes:

One of the things I learned from the engineer at BBK was that the gray paint on the back of the throttle body was called pre-sludge. This is not a coating to keep off the sludge. But rather to put it on from the beginning. As odd as this sounds, Ford didnít like the fact that if there was no coating at all, then the car would be set to idle properly during assembly. Then after the car had 5000 miles, the sludge would be building up on the back of the throttle body and it would start to seal off the slit around the butterfly during idle. This would cause the car to idle low and possibly die. It was easily adjusted my turning the set screw, but most people didnít know that so they took their cars in to the dealer. So they apply this coating to act like the sludge from the very beginning and allow for the idle screw on the side of the throttle body to not have to be adjusted later.

The last item is a word of caution. As stated above the

Edlebrock throttle body is actually made by BBK. If you do what I did and

buy a Edlebrock throttle body from an internet company, then there is a

problem if there is anything wrong with the part. I bought mine from

RaceSearch.com and found that even if I screwed the gold screw in the

bottom in all the way, air still could go through the small hole between

the 62mm bores. RaceSearch.com said that they were unaware of any problems

with the parts. So if I wanted to send it to them, they would put it on a

shelf until an Edlebrock rep cam by and he would decide if they would

provide a warranty replacement. They told me I could return it directly to

Edlebrock and take my chances. When I called Edlebrock they didnít know

anything about it and told me to call BBK directly. I eventually sent the

part back to BBK and got another one. When I returned it I thought there

was an additional problem as well. That turned out to be the set screw mis-adjustment

I talked about above. I did get the problem solved by BBK, and for the

most part I donít have anything bad to say about them. However, I will

say that they do not usually deal directly with the public and they are

not really set up for it. They donít get in a hurry and they donít

understand someone who does.

Kenny Parker